LCA Vetting Process

A GUARANTEE OF QUALITY

The Lead Contractors Association regularly vet all of their members – but what exactly does vetting mean, what is involved and why is it so important?

Vetting is an on site inspection by a LCA Vetting Officer to look at the work carried out by a member of the LCA. It is a mandatory requirement of LCA membership and there are no exceptions. On site inspections require physical access to the roof (not just a quick look up from ground level) and may even require leadwork to be lifted so that sizing and fixing details can be checked and verified. Fortunately one of the benefits of working with lead sheet is that it can be lifted and replaced without detriment to its appearance or performance and our vetting officers take full advantage of that opportunity for close up inspection.

LCA vetting officers are making sure that the leadwork conforms to BS6915, the Code of Practice for lead sheet roofing and cladding. This is because lead sheet is a soft metal that when fitted is subject to temperature changes that cause expansion and contraction, so has to be sized and fixed correctly to allow for this movement and yet remain securely in place. It is therefore essential to follow the rules of BS6915 (detailed in the LCA Lead Sheet in Roofing, The Ultimate Guide to Best Practice) in order to gain optimum performance from the lead in situ and it is one of the reasons why lead sheet has such an unrivalled long term life span.

Vetting also provides the opportunity for the vetting officer to discuss the project being inspected with the LCA member in person and perhaps explore why a particular detail was used. In this way they can be satisfied that the installer not only knows how to use the metal but also why that detail was required i.e. there is an understanding of the theory / design aspects behind installing lead sheet. Any detail that is found not to conform with BS6915 must be corrected or the contractor risks losing their LCA membership. A formal report of the inspection is compiled by the vetting officer and sent for approval, grades are published in the directory and on the LCA website.

Associate Members

SUPPLIERS SUPPORTING THE QUALITY AIMS OF THE LEAD CONTRACTORS ASSOCIATION

Latest News

LEAD CONTRACTORS ASSOCIATION

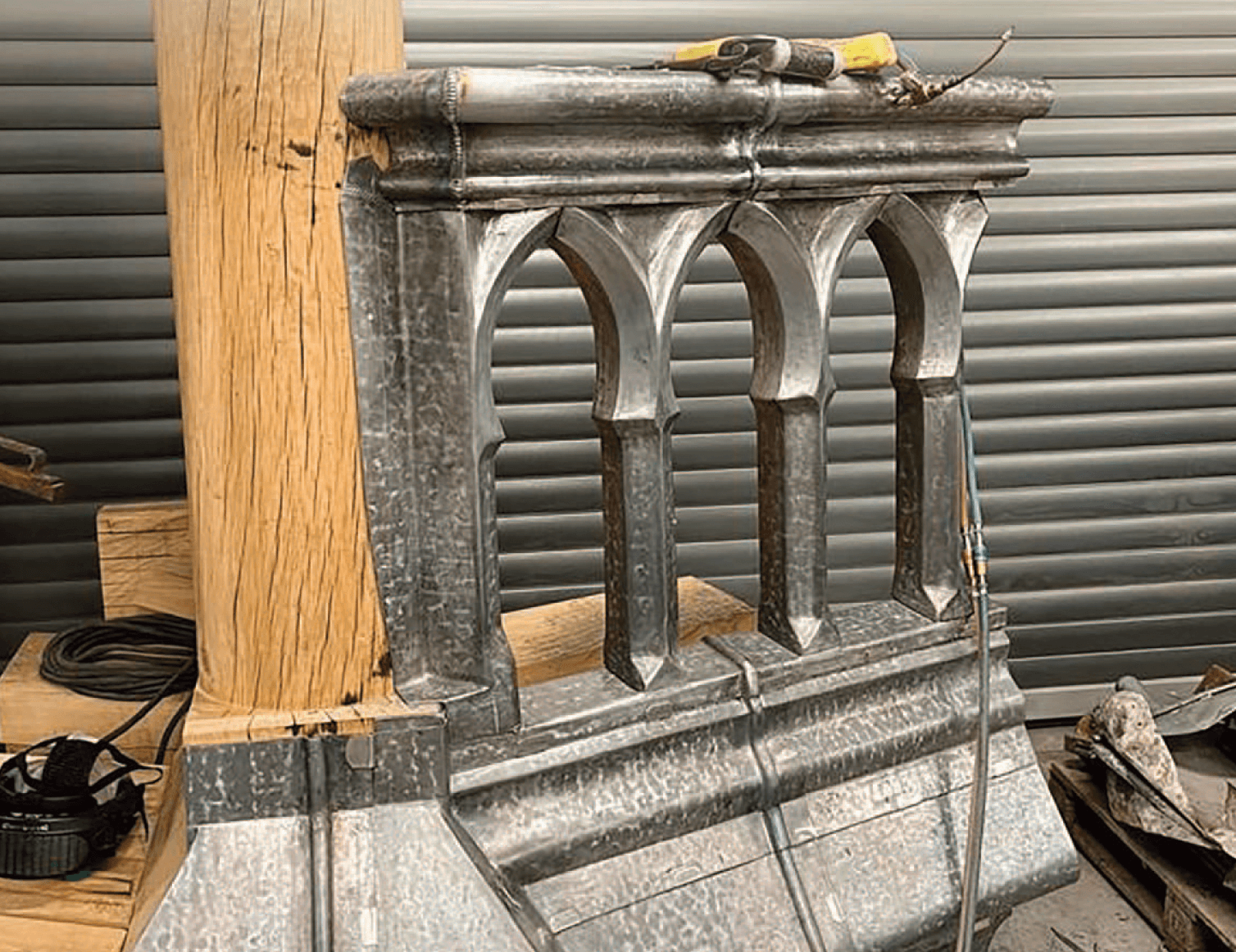

Restoration of Notre – Dame de Paris

LCA Associate Member, Sand Cast Lead Conservation Ltd, supply sand cast lead sheet for the restoration of Notre

Outstanding Service Award for David White

Alasdair White LCA Chairman Receiving David White Long Service Award from Tim Acland The LCA Membership,